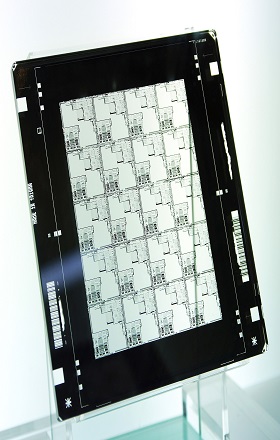

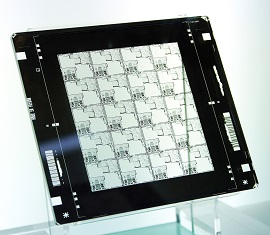

Photo Mask

A Photomask is an opaque plate with transparencies that allow light to shine through in a defined pattern. Lithographic Photomasks are typically transparent fused silica blanks covered with a pattern defined with a chrome metal-absorbing film.

A set of Photomask, each defining a pattern layer in integrated circuit fabrication, is fed into a photolithography stepper or scanner, and individually selected for exposure. In double patterning techniques, a Photomask would correspond to a subset of the layer pattern.

We offer High Resolution Photomask Fabrication on Chrome, Emulsion, Film, and many special products. Our comprehensive range of products are all available at different resolutions and schedules and provide bespoke solutions for non standard products.

Chrome Photomasks

Our mask type is Low Reflective Chrome Oxide on Quartz (Fused Silica) Soda Lime Glass. These are very high resolution, easy to clean, and hard wearing. Soda Lime Glass is a very popular low cost alternative to quartz with high light transmission in the visible spectrum. Quartz has a much lower thermal expansion, and a slightly higher light transmission rate. The chrome coating has an OD >3 and has a low reflective oxide coating on the top surface, but equally can also be supplied in high reflective or blue oxide variants. We offer different materials, special chrome coatings, various thickness plate etc.

Special Material Masks

We provide products with non standard materials and coatings, such as Aluminium, Gold, Black Chrome, Opal Glass, Borofloat etc.

Emulsion Glass Masks

Emulsion on Soda Lime Glass surface means that this a delicate surface and this is usually a lower cost alternative to chrome, especially when large sheet sizes are required.

Film Photomasks

We provide High Resolution, Low Resolution and Large Format flexible film Photo-tools and provide the most comprehensive film with the best possible image quality and accuracy.

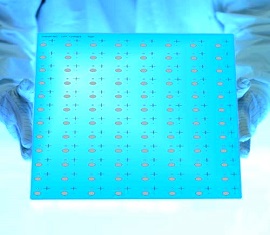

Machine Calibration Charts

Our Vision Machine Calibration Plates are used extensively by the world’s leading manufacturers who need low cost, high accuracy calibration patterns that align and configure their machine vision systems. Typically supplied as dot patterns on glass plates, these large plate reticles are available as standard products from defined and tested patterns, through to full custom beptoke service from as little as a single plate. Supplied with calibration and measurement certificates, our calibration plates can be relied upon day after day.

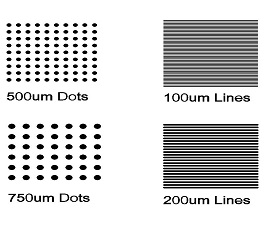

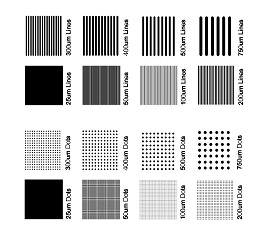

Resolution Targets

Our resolution test targets are widely used to measure the resolution of imaging and vision systems. The patterns are tightly controlled and very accurate, can be supplied with certificates of measurement, and are generally made by a Photolithographic process. By identifying the largest set of non-distinguishable lines, you can determine the resolving power of your vision system.

Vision Calibration Charts

Imaged optical components, sometimes with intricate shapes, can be manufactured for industries that use Graticules, Reticles, Encoders, Apertures, Scales, Disks, Slides, Laser Ablation.... andthe list is endless. We have a range of standard Test Targets and Micrometres that are with various patterns and for many varied applications. We also specialise in a custom manufacturing service starting at single units with specialised materials, shapes, patterns and coatings.